Metal is a fairly common material for the construction of gazebos in personal plots. And this is understandable, because unlike a tree, its cost is much lower. An additional advantage is easy care and maintaining the original appearance. Due to these properties, as well as the ability of the metal to withstand high loads, good compatibility with any finish, this material is increasingly used in the construction of gazebos in summer cottages and household plots.

Types of metal gazebos

Choosing metal as the main material for building a gazebo on your site, the first thing to do is decide on the type of future structure. In this case, first of all, you should focus on your construction skills, as well as the availability of special tools and equipment. It is necessary to take into account not only the benefits, but also the features of each variety.

From a profile pipe

Profile pipes are most often used for the construction of the frame structure.

- This choice is explained by the following advantages:

- strength and resistance to various deformations and mechanical damage with low weight;

- durability;

- the ability to create any, even the most complex frame structures;

- the accessibility of the casing of the frame from shaped pipes with any material (wood, plastic, polycarbonate and others);

- low cost in comparison with forged metal;

- ease of operation (profile pipes are easy to drill, cut, etc.).

Did you know? The birthplace of the first arbors is Egypt, and the first mention of these structures was found in the tombs of the pharaohs.

There is a minus: using this material to build a gazebo with your own hands will require welding skills. Most often, the manufacture of gazebos is carried out using hollow profiles of square or rectangular section, the material for which is ordinary or galvanized steel. When choosing, you should pay attention to the length, width and wall thickness - it is these indicators that will be responsible for the ability of the entire structure to withstand the weight of the roof, as well as other mounted elements. It should be borne in mind that the cross-section of the supporting profile is usually larger than that of the jumpers.

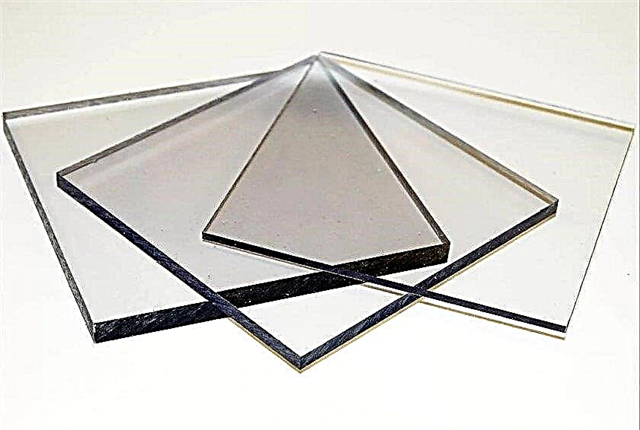

From metal and polycarbonate

Along with metal, polycarbonate is often used, which acts as a casing for the gazebo. The tandem of these materials has many advantages:

- high ability to withstand mechanical damage (for comparison, glass is 200 times less durable than polycarbonate);

- resistance to corrosion;

- blocking the penetration of ultraviolet rays up to 90% (subject to treatment with a protective composition);

- convenience in processing;

- refractory properties;

- ease of further care (removal of contaminants, repairs, etc.).

Today, there are two main types of polycarbonate used in the construction of arbors:

- Cell - due to its cheapness, it is the most popular option for lining among summer residents. Able, in the presence of tinting, to obscure the arbor well, however, it is characterized by low heat transfer, and therefore requires active blowing of the structure on a permanent basis (that is, the arbor must be open), because it will be too hot inside in the summer.

- Monolithic - is a translucent plastic, its structure is similar in appearance to glass. It has high strength and resistance to chemicals, and also provides high sound insulation.

Forged steel

Forged steel belongs to elite materials and has a high cost. This is due to the impressive weight of the frame and decorative ornaments, which are a prerequisite for welding. Also, such a gazebo is recommended to initially be installed on supports, thereby slightly raising it above ground level. However, in addition to a truly noble appearance, such designs do not cause problems in future care: it is enough to protect them from corrosion with the help of an annual update of the protective coating.

Did you know? According to the Taoist practice of developing the Feng Shui space, the location of the gazebo in the southwestern side of the site can significantly improve family relationships.

Preparation for construction

In the process of preparing directly for construction, several key points should be taken into account:

- Decide on the design. In total there are 2 main types of arbors: open, which is a traditional summer option. It consists of support pillars, a low perimeter fence (parapet) and a ceiling (roof), which is able to protect from sunlight and precipitation. The lightness of this design allows the use of single or double gable, multi-forceps or hip upper coatings. Also, arbors can be closed. This means that they will have the same design, which is complemented by blind or glazed walls. In this case, it is required to foresee openings for future windows and doors in advance.

- Choose a form. In principle, metal arbors can have any shape, but the most popular are square, rectangular or polygonal structures. The latter option is usually used in open buildings.

- Pick up materials. The most common option is profile iron pipes. In this case, you can use round, but the most popular is a square or rectangular section. Their wall thickness should be at least 2 mm. As a roofing material, corrugated board (for corner roofs) or polycarbonate sheets (in the case of single-pitched or semicircular structures) are used. When choosing corrugated board, you should pay attention to the labeling of the material (for example, "NS" indicates the versatility of use, and "N" is intended for load-bearing structures). If the choice fell on polycarbonate, then its thickness is chosen from 8 to 12 mm. The wall covering of the arbor can be made using wood (in this case, additional processing of the material with an antiseptic will be required) or the same polycarbonate.

- Calculate materials. To do this, the required number of pipes is calculated taking into account the length (50 cm per recess should be added to the height of the arbor) and the cross-section. Additionally, the list may consist of sand and cement for the foundation, profiles for support pillars (usually 40 × 40 mm or 50 × 50 mm), pipes for wall and frame mounting (40 × 25 mm), as well as roofing material.

- Prepare tools. Due to the fact that the durability of the entire building is related to the quality of pipe fastening, special attention is paid to this item. The list may consist of an electric welding machine and its electrode, tape measure, level, rope and stakes for marking, shovels, as well as containers for mixing cement, auger, reinforcement, drills with drill bits for metal, hacksaws, screws and nails.

Seat selection

An important point in preparation for construction is the choice of a place for a future gazebo. When choosing the most suitable place for the gazebo, several key factors should be taken into account:

- The size of the future building - a massive structure will cover the view, and therefore it is better to place it behind the house, next to the fence. But the average dimensions of the gazebo will allow you to choose any site, but it is better if large trees grow nearby, which will provide additional shade and protect from prying eyes. In the process of placing portable structures, the main thing is that they do not block the entrance to the house.

- Optimal conditions - in large areas, if possible, the shores of reservoirs or the territory near the fountains will be a suitable place. This approach will help keep freshness and cool. Also, places with strong drafts should be avoided, and the entrance to the arbor should be located on the leeward side.

Important! The location of the gazebo should also comply with fire safety standards: if a barbecue or barbecue is provided in the building, its distance from the apartment building must be at least 5 m, and from the fence of the neighbors — from 8 m.

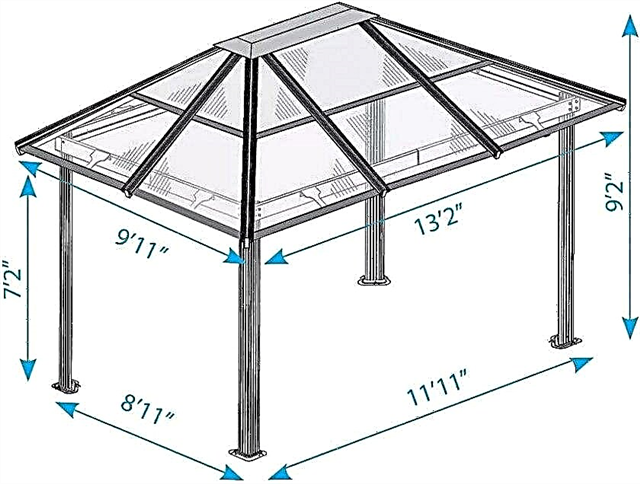

Dimensional Drawings

The project of the future structure can be completed by following one of the presented paths:

- find on the Internet options for free drawings, along with ready-made specifications and calculations;

- buy a prefabricated structure, and carry out the installation yourself;

- order a finished gazebo, which is also called "turnkey";

- to carry out all the stages of planning yourself.

In the latter case, you must adhere to the following algorithm:

- On the paper you need to put a plan of the site, determining the optimal place for construction.

- Then, on the diagram, draw a future gazebo: determine the bearing walls and tables, choose the type of foundation, taking into account the relief of the site (for example, the presence of swamps or drops).

- After sizing, calculate the material.

- As the last stage, choose the rafter system and the option of roofing material.

When choosing sizes, it is necessary to take into account that the ceiling height of the gazebo should be at least 2.2 m (for a comfortable stay inside). Width and length will depend on the total area of the personal plot (2 × 3 m is considered the optimal structure). In the event that a barbecue or barbecue is initially provided, the area will need to be increased. For this purpose, they set aside a special corner for equipment installation (usually, a grill needs no more than 1.5 m²), and the seats are located at some distance from the place of cooking.

Important! To avoid errors when calculating angles, it is recommended to choose arbors of a rectangular or square type, which are the best option for self-construction.

Step-by-step construction

Before proceeding directly to the construction, it is necessary to prepare the place chosen for it. To do this, remove the top soil layer, about 15 cm thick, on the site, and carefully level it. Next, markup is applied, namely: determine the location of the supports (they must be on the same line, and their distance from each other is regulated by the calculations in the drawing). This operation is carried out using stakes installed in the corners of a future building, and a rope. After that, you can proceed directly to the construction of the gazebo.

Foundation

The gazebo, whose dimensions do not exceed 4 × 6 m, does not need strong strengthening, and therefore the columnar foundation will be the best option.

For this:

- A garden drill needs to be made at the corners of the funnel with a depth of about 50 cm. The bottom should be covered with a layer of sand 5 cm thick.

- Then install supports with reinforcing bars welded at the ends.

- The voids between the walls of the recess and the pillars must be filled with concrete, making sure that they maintain a clearly vertical position.

- After pouring, it takes several days to completely dry the solution and carefully fix the supports.

In the event that the dimensions exceed the standard or it is planned to install a barbecue, pouring the strip foundation will be required.

In the event that the dimensions exceed the standard or it is planned to install a barbecue, pouring the strip foundation will be required.

To do this, you need:

- Dig a trench at least 50 cm deep.

- Along its perimeter, erect a timber formwork.

- Pour crushed stone inside the formwork with a layer of about 5 cm, and then mount the frame from the reinforcement.

- Pour concrete over reinforcement.

Construction welding

After fixing the supports, you can proceed directly to the installation of the gazebo, which is performed by the welding method:

- First of all, the lower jumpers are attached to the supports (height - about 0.8 m). Then another belt is boiled, but using pipes with a cross section of 40 × 25 mm. These actions will provide the basis for the frame structure.

- The upper lintels, which will be the base of the roof, are welded to the ends of the posts. At this stage, it must be ensured that all supports are of equal length.

- Then, pipes with a section of 40 × 25 mm are attached to the ends by welding at a height of about 1–1.5 m - they will act as parapets.

- On the lower horizontal structural elements, transverse logs are welded for future floor laying.

Video: DIY gazebo

Thus, the welded frame is ready and you can proceed to the roof of the gazebo.

Roof

Usually, the most cost-effective material is used as a roof - polycarbonate. In this case, its cellular type with a thickness of at least 8 mm will be the best option. Its fastening is carried out using special bolts with thermal washers, which are aimed at maintaining the integrity of polycarbonate. The whole process is not particularly difficult: the material is cut into sheets of the right size, and holes for fastening are preliminarily prepared in the pipes. After laying, using special strips, the ends of the sheets are closed. Such an approach will not only give greater aesthetics to the appearance, but also provide additional protection for polycarbonate from the negative effects of the external environment.

Sheathing

When choosing a casing should focus on personal preferences. Having special skills, the gazebo can be decorated with an ornament of metal or a wooden crate. Also, for these purposes, profiled sheets and carbonate, lining, block house, siding are well suited. In general, the lining performs only a decorative role, and therefore special technical requirements are imposed on it.

Floor laying

The best option for laying floors in gazebos made of iron is a wooden floor, for example, from a pine board or from larch, which refers to more expensive flooring, but also better.

The procedure itself does not take much time:

- on the lower harness, lags with metal corners should be fixed;

- on top - lay the boards, leaving small gaps between them (for moisture to escape).

Dressing

After completion of construction, the most pleasant moment comes - the interior design and decoration of the gazebo.

In the process of choosing a finish, you should focus on such its main characteristic as moisture resistance, and therefore the following materials are considered the most common:

The external decor of the gazebo can be accompanied by lighting - lights or lanterns. Also, on metal buildings, climbers that let on racks look great. During their growth, you can get a shadow and cool.

When arranging the interior, everyone can express and realize their creative potential. The main thing is to adhere to the “golden mean” and not to get out of a single style. You need to choose the right furniture, which will have lightness and stability. An important point is the installation of a light source inside the gazebo, as well as the study of interior details: the selection of tablecloths, curtains, pillows. They will be able to give cosiness to the whole room. If the design allows, then the ideal option is to install a barbecue or barbecue, which will allow you to cook without leaving the arbor.

In general, metal is the material that allows owners of summer cottages or household plots to get interesting and inexpensive designs. Of course, such works will require some skills, but independent construction makes it possible to create an exclusive author's masterpiece, in which it will be especially pleasant to spend time with family and friends.