Newcomers to beekeeping, first of all, think about the question: which hives are better to choose for a family of bees. This article details hives with 10 frames, their features and advantages, manufacturing instructions for ready-made drawings.

Description and characteristics of the 10-frame hive

A beehive for a dozen frames is called Dadanovsky, in honor of its inventor Charles Dadan. The French beekeeper, in addition to breeding bees, was studying their behavior. The design interested many beekeepers, as it was lightweight and easy to maintain. In addition, it allowed to receive stable collections of products. Convenience is given in the ability to add add-ons as the bee family grows. The vertical arrangement of the frames facilitates the work of collecting products and checking the condition of insects. The lightness of the hive is ensured by its smaller size in comparison with standard buildings, which also allows saving on materials.

Convenience is given in the ability to add add-ons as the bee family grows. The vertical arrangement of the frames facilitates the work of collecting products and checking the condition of insects. The lightness of the hive is ensured by its smaller size in comparison with standard buildings, which also allows saving on materials.

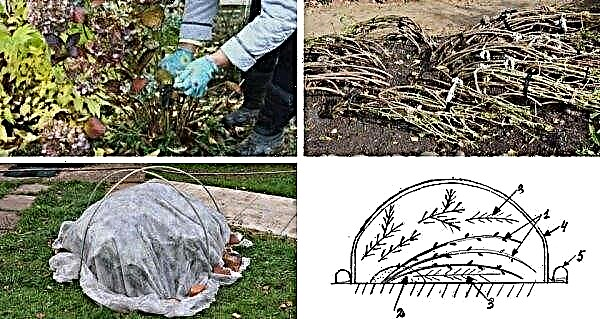

In detail, all the components of the structure are visible in the figure below:

Did you know? The Elfinsky honey variety is considered the most expensive in the world, the price per liter is 5–7 thousand euros. It is mined in Turkey in the Sarikair cave with a depth of more than 1.8 km.

Advantages and disadvantages of the 10-frame hive

The advantages of bee houses on 10 frames are noted by many beekeepers. The design is considered the best option for beginners.

- Its advantages:

- a framework where the width is greater than the height prevents swarming due to overpopulation;

- increased honey collection up to 50 kg from the hive;

- small dimensions and weight, there is no need for an assistant (single-hull);

- the construction is sufficiently isolated from external factors, the family does not spend time protecting it from the cold;

- quick access to frames;

- it is possible to make a partition.

- Design flaws are noted mainly by beekeepers who have mobile apiaries or owners of large honey lands:

- there are few frames for laying eggs, which necessitates an additional housing;

- with an additional body, loading and unloading operations when moving are complicated;

- the frames are small, which complicates the collection process.

DIY instruction

The hive can be built independently by choosing a single-hull or multi-hull option.

Drawing of the 10-frame "house":

General form

To navigate in the diagrams, consider the dimensions on the example of the case (in the drawing this is the lower part):

a) front shield:

- height - 370 mm;

- width - 530 mm;

- wall thickness - 40 mm;

b) the sides:

- height - 370 mm

- width - 490 mm;

- thickness - 40 mm;

c) internal dimensions of the housing: 450 × 320 × 450 mm;

g) the size of the folds:

- single-case version - 20 × 10 mm;

- multi-case version - 12 × 10 mm;

- height - 300 mm;

- width - 435 mm.

Material selection and preparation

The traditional and most commonly used material is wood. You can use needles, but not resinous or hardwoods, the latter are best suited for frames. Deciduous wood has a softer structure, into which a nail easily enters without splitting.

The list of breeds used:

- spruce;

- cedar;

- poplar;

- Linden;

- aspen.

Important! It is recommended to use new wood, without traces of decay and pungent odors: bees can abandon a house with unpleasant aromas.

To work with wood you will need the following tools and materials:

- woodworking machine;

- milling cutter;

- pencil and tape measure;

- board thickness of 40 mm and 15 mm;

- wood glue;

- brushes and paint.

- The wood is cut to the desired length and width, depending on the purpose of the workpieces.

- Then it must be carefully sanded.

- Grind the edges under the lock in the form of a thorn groove.

Strap Making

In order to keep the assembled body shields well, thin strips with a section of 25 × 12 mm are glued along the entire length of the inner side. Subsequently, these planks will also serve as additional insulation. In addition, the edges of the planks will become a support for the frames.

Hive collection

Shields are assembled by gluing grooves and spikes with resistant wood glue. For a snug fit between the components of the shield, after docking on the upper part you need to knock out with a hammer (use a hammer to lay the laminate so as not to damage the upper spikes). Shields are assembled in the same way for the store, in the lower side of the boards of which there is also a groove for the spike of the top of the case.

Store options:

- height - inner 145 mm, outer 165 mm;

- width - inside 450 mm, outside 530 mm.

Important! Please note: in the drawing, the height of the store frame is less, the mandatory clearances of the interframe space are also indicated.

To cover the hive take a board with a thickness of 15 mm. Product height 120 mm, width 530 mm. The upper shield is wider - 585 mm. Before collecting all the parts in one design, they must be carefully painted over to protect them from the effects of wind and precipitation.

Drilling of tap holes and ventilation

A summer house in the lower part of the bee dwelling is made over the entire width of the hull. Its shape may be rectangular or oval, at the discretion of the beekeeper. A plate is placed in front of the tap hole for the convenience of flying insects, about 35 mm wide.

The notch located at the top can have dimensions of 20 × 10 mm. Several holes with a diameter of not more than 15 mm are drilled on the sides of the structure. The holes are usually provided with lattice material.

Work with beehives

In the spring, beekeepers finish building stationary beehives with a second building, additional stores are also added.

After the main melliferous plants bloom, around the end of July, beekeepers begin to take honey. Bees at this time are not aggressive, they are busy preparing for winter on the lower floors of the "house". In the same period, the farmer must provide the bees with top dressing so that the percentage of egg laying does not decrease.

The uterus lays offspring at the site of the largest accumulation of bees. Feeding will attract them to the combs, and this in turn will attract the uterus.

In August, the upper part of the hive is inspected, full honey-pergovy frames are removed - they will serve as food in the winter. At the same time, the upper tiers serve as a kind of dryer for honeycombs.Did you know? The author of the idea of using wax in hives was the beekeeper and inventor Johann Mehring, famous in the 19th century. In 1860, for this invention, Mehring received the prestigious beekeeping award in Hanover.

Autumn work consists in examining the entire dwelling, forming a winter nest for the family. Several honeycombs are left for spring feed, old honeycombs are removed. A store is installed under the body, which will serve as an insulating frame space. In the nest itself, you need to place a sealed honey frame, in total up to 30 kg of stock. The side walls are insulated both outside and inside with a special pillow. At the end of autumn, keeping an apiary with bees takes place in a winter house.

In the first days of the thaw, in early April, the first flyby takes place. During this time, the beekeeper manages to replace the bottom, replenish feed supplies and rearrange the nesting "room" to a clean bottom. The store is not needed at this time, it is deleted, as well as empty frames. It is too early to remove the insulation from bee houses.

Around the end of April, a general cleaning of the hive is carried out. Preventive drugs are given to insects.

In early May, the hatching offspring replenishes the family, the nest is expanded, adding the right amount of frames. A second building is placed under the nest, equipped with land and wax - this gives the replenished family room for activity, and in addition, reduces the risk of untimely swarming. Over the summer, the family manages to completely "rebuild" a new building.

June is the time to fill the honeycombs with nectar, it will be useful to install a store above the nest. Then you can put another one, between the slot and the original store. This will serve as an incentive for bees to replenish their own winter food supplies.

Video: Work with 10 frame hive

Useful tips for beekeepers on making a beehive

In every business, and beekeeping is no exception, there are subtleties.

Recommendations for the construction and operation of bee houses:

- To increase the brood nest, you can increase the height and number of frames, or place the magazine under the case.

- Each hive should have a pantry, which is located in the frame section. This is necessary for the autumn "drying" of low-copper frames.

- In addition to “drying”, the frame space serves as a kind of insulation and facilitates hygienic care of the bottom of the building. It is much easier to give the family additional nutrition, medicine if necessary.

- Wood must be well dried and protected from moisture with special materials. Otherwise, under the influence of external factors, it will quickly lose shape.

To build bezfaltsevyh hives you need to use a calibration pattern when fitting parts. This is necessary so that the planes of the components of the "house" are perfectly aligned. Typically, a steel sheet of suitable sizes, up to 8 mm thick, is used for these purposes.

So, the Dadanov design is convenient to operate and easy to assemble. Any beekeeper can upgrade the original model to his needs.