Each beekeeper should not only know everything about bees, but also be well versed in the design of a bee house, and also be able to improve it if necessary. Indeed, the productivity of these workers depends on the quality of housing conditions. Below you will get acquainted with the varieties of hives and learn how to make one of them with your own hands.

Types of houses and features of their designs

According to the type of construction, hives are:

- collapsible and non-collapsible;

- vertical and horizontal;

- multi-hull and single-hull.

Non-demountable buildings are impractical, because they are difficult to care for. The most popular are collapsible, frame hives, it’s easy to clean them and the frames with honey are free to get. If necessary, the frame hive can be increased by delivering a new housing (vertical) from above or expanding it in length (horizontal). Multi-risers are easy to disassemble and carry. The horizontal design is more comfortable, but heavy, more suitable for a stationary apiary.

Did you know? In every hive there are guard bees that conduct “face control” by smell. They will not miss a bee with a strange smell.

Common types of bee houses:

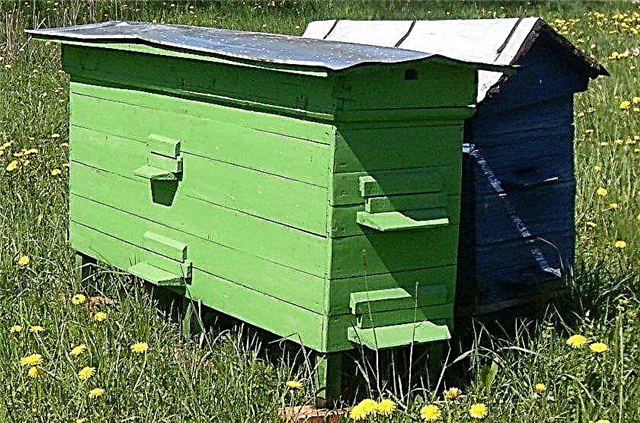

- Dadanovsky (Dadana Blatt) - the most popular model in small apiary farms, due to its lightness, simplicity and spaciousness. This is a vertical multi-frame design with 12 frames. It consists of a lower nesting enclosure, in which the bee family hibernates, a store superstructure and a roof cover. With the increase of the bee family, new buildings are built on top. All parts are easy to remove and transport.

- Alpine (Roger Delon) - vertical bee "high-rise", designed for professional farms for hundreds of bee families. Several socket housings are built on top of one another. Partitions, separation grilles and ventilation openings are absent. For this purpose serves as a notch. This design is closest to natural conditions and resembles a hollow. Due to their compactness, these hives are an excellent option for small areas and for transportation.

- Rutadeveloped by Langstrot in the 19th century. - A riser of several buildings (2–6) for 10–12 frames; it is used more in industrial beekeeping.

- Cassette hive called so, thanks to a special design. In the common housing one above the other are several retractable socket housings-cassettes. Families are separated by thin plywood partitions or gratings. The walls of the hulls are double, which makes them warm. Such a multi-story house is made of wooden boards soaked in wax. This measure protects bees from disease.

- Ukrainian sunbed - horizontal single-hive hive. It is a large elongated box, divided by a partition in half and designed for 2 bee families. The walls of the case are insulated, so it is warm in the winter. It is heavy and dimensional, inconvenient for transportation. Its dignity is easy to care for bees and their housing. Suitable option for beginner beekeepers.

Criteria for choosing finished houses

When buying a finished bee house or if you want to do it yourself, you must first decide on the model.

When choosing a suitable design, the following criteria must be taken into account:

- climate and weather conditions in the region: if spring and summer are cold with characteristic frosts, warmed, double-walled hives are needed, they can be left to winter on the street;

- possibilities of honey collection in the area: loungers, two-hulled and multi-hulled are suitable for copious medical gatherings; for meager - small, single-hull ones;

- apiary variety: heavy beds and double-hull houses are suitable for stationary, light, compact, multi-hull, expanded polystyrene for transport;

- planned methods: if you need to create another family with a new uterus, you need a sunbed;

- apiary sizes: for a large farm, beehives are ideal, from which you can quickly pump out honey, for example, two-hull;

- experience in beekeeping: It will be easier for beginners to start with a simple sunbed design.

To find out what types of hives are successful in your area, you can consult with experienced beekeepers and observe their work.

To find out what types of hives are successful in your area, you can consult with experienced beekeepers and observe their work.Homemade Beehive Requirements

Experienced beekeepers recommend the following rules when building a makeshift house:

- building material must be taken durable, moisture-proof, to protect insects from bad weather conditions;

- you need a heater that will keep warm inside in winter, and comfortable coolness in summer;

- it is desirable to have not one, but several letkov, which, according to the weather, can be closed and opened;

- there should be enough space in the hive for the movement of bees, for brood and honey;

- the design should be convenient for the beekeeper so that he can easily collect honey to clean the house and take care of the family, you need an opening lid and / or a removable bottom.

How to make a house with your own hands?

Having familiarized yourself with different types of bee houses and choosing a suitable model, you can proceed with preparations. It is necessary to draw a drawing with accurate calculations, choose a place and prepare the materials and tools necessary for the construction.

Seat selection

Before starting the construction of the hive, you need to find a suitable place for it. No matter how comfortable the house may be, if there are no blooming honey plants near it, the family is unlikely to be productive. The hives need to be installed on a flat area, preferably with a slight slope to the south, east or west, so that rainwater flows. An apiary should be protected from drafts and strong winds. To do this, it is installed near a fence or wall. Tall plants can serve as a protective wall: sunflowers, corn, bushes or trees. Such a hedge will provide houses with a shadow in the summer heat.

An apiary should be protected from drafts and strong winds. To do this, it is installed near a fence or wall. Tall plants can serve as a protective wall: sunflowers, corn, bushes or trees. Such a hedge will provide houses with a shadow in the summer heat.

Important! You cannot install an apiary near rivers and lakes, factories, railways and highways, high-voltage power lines, schools and kindergartens, livestock farms and plantings treated with pesticides.

Tools and materials for manufacturing

Today there is a wide variety of materials for making bee houses.

To choose, you need to learn about the pros and cons of each of them:

- wood - traditional material and as close as possible to the natural living conditions of the bees, you need boards of soft breeds (preferably cedar), dry, even, smooth, notched, 5 mm thicker than the planned wall thickness of the hive; plus - low thermal conductivity, minus - absorbs moisture;

- plywood - environmentally friendly and long-serving material, can surpass wood in thermal insulation and ensuring dryness inside if it is painted with acrylic paint and insulated with expanded polystyrene;

- polystyrene foam and polystyrene foam - the materials are light, cheap, well-retaining heat, easy to use, minus - fragile and need to be painted to protect against weather conditions.

Tools that can be useful in the manufacture of bee housing:

- ax and hacksaws;

- hammer and nails;

- chisel, planer and jointer;

- drill and other power tools;

- corner studs and glue PVA.

Step-by-step manufacturing instructions

Since it is easier for a beginner to start with a sunbed, the instructions for making it are given below.

Have to take:

- materials: wood, galvanized sheet, carrying handles;

- tools: hammer and nails, hacksaw and ruler, drill and drill, self-tapping screws and glue, chisel;

- frames - 24 pcs.

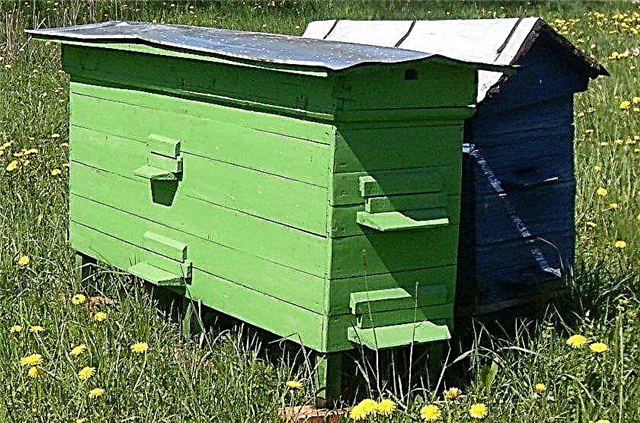

Important! The hive can be painted in blue, yellow or green, preferably white, which is easier for bees to remember. Red color does not fit, because they do not see it.

Dimensions:

- case - 87 × 56.5 × 63.5 cm;

- roof length inside - 81 cm, outside - 93.5 cm;

- bottom thickness - 3.5 cm;

- diameter of the upper notch - 2.5 cm;

- lower letlet - 1.2 × 14 cm;

- frames - 43.5 × 30 cm.

Cut parts according to drawings:

Instruction:

- To collect the bottom from the flooring and 2 battens, connecting them with nails and soil.

- Assemble the walls and attach them to the bottom, leaving a protrusion of 2 cm.

- In the walls, front and back, make grooves of 1.8 × 1.1 cm to insert frames.

- Cut a notch in the lower part of the front wall.

- Attach a gate valve and an arrival board.

- Assemble the roof from the boards and attach the hinges.

- Beat the finished roof with a tin.

- Cut a hole 20 × 0.03 cm for ventilation in its rear part.

- In the front wall, drill a notch of 2.5 cm.

- Cover the flying holes with a net.

- Attach the legs to the bottom.

- Ready house to process with drying oil and paint.

- Attach carry handles.

Video: how to make a hive. Production, assembly and complete instructions

Accommodation and arrangement

The correct situation in the house, as well as the presence of all vital details inside, will contribute to the well-being of the entire bee family. Almost all the space in the hive is occupied by frames whose dimensions correspond to the internal dimensions of the hull. Each frame consists of two horizontal bars, upper and lower, and two thinner side bars. Wire is pulled from top to bottom through holes drilled in horizontal bars. Then a special wax plate is attached to this wire, which will serve as the basis for future honeycombs. The number of frames must match the capabilities of the family, as it grows, new frames are added for the construction of new cells.

In addition to the framework for honeycombs, the house should have:

- two diaphragms that can be freely moved depending on the size of families;

- a feeder made from a nomadic net and installed under the roof;

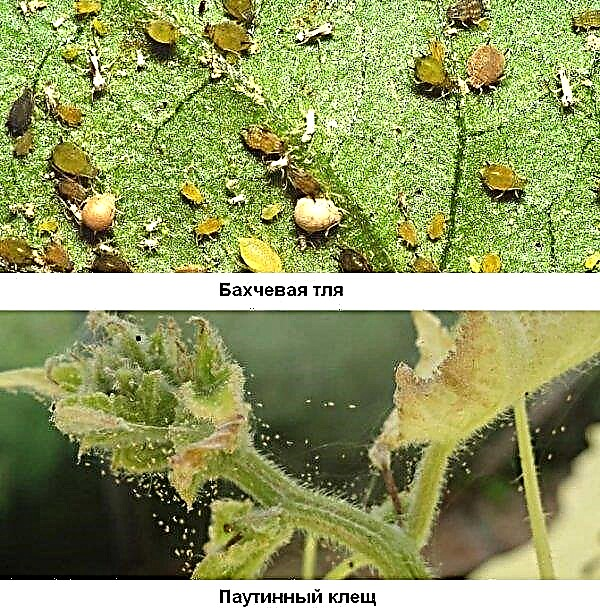

- galvanized mesh above the bottom for protection against ticks;

- a small heater no more powerful than 10 watts for winter heating.

Of great importance is the placement of beehives in the apiary. With the correct position of the house, the bees almost do not wander, their working day increases as much as possible, and, consequently, the honey collection increases.

Did you know? A bee can smell the aroma of a honey plant blooming a kilometer from her house.

The houses are placed correctly if:

- at a sufficient distance from each other:

- they have landmarks (buildings, trees, bushes, multi-colored flags above the hives) and are painted in different colors;

- letki are directed north or northeast (this increases daylight hours);

- in front of them there is a free flight space of 3-5 m;

- they are at a height of 20–25 cm from the ground (on supports or legs).

Beekeeping is a time consuming and responsible business. But if the bees are provided with comfortable housing, they will generously thank their owner with honey.