There are many types of hives. Beekeepers, in order to facilitate their work, came up with different designs. One of such constructive solutions convenient for bees and the beekeeper is the device of the Udav hive, created by the beekeeper Vladimir Davydov.

Description and design characteristics for beekeeping

The Udav hive is a construction of 9–11 small-sized buildings, standing on a combined bottom with an anti-varroatose grill. In each case there are 9 frames of a non-standard size (11 × 28 cm).

Did you know? The inventor of the first collapsible frame hive (1814) was Peter Ivanovich Prokopovich from the village of Palchiki, Kiev province. For his contribution to beekeeping, he was awarded the Order of St. Vladimir IV degree.

Such small dimensions allow you to do without pulling the wire. They have a cut in the upper bar, into which a piece of wax is conveniently inserted. The cover has a layer of 3 cm, where you can insert a foam sheet for insulation, and a slot for ventilation.

Pros

The biggest advantage of the Davydov hive is the simplicity of its maintenance.

- Among the advantages, it is worth highlighting such features:

- Light weight enclosures. Each of them weighs no more than 12 kg, is easy to get and carry.

- Fast frame mounting through slots. Simplicity and speed of maintenance of bee frames, since you do not need to stretch the wire. In addition, 2 such frames are just placed in the honey extractor.

- Thanks to the small parameters of the bee’s frame, it is faster to fill it completely. They are conveniently used to obtain honeycombs for sale.

- The hive prepares faster for winter thanks to unified frames and hulls. Usually a family hibernates in 5 buildings.

- The design has good ventilation, due to the large number of notches and the ventilation hole in the cover.

- Convenience of moving along the hive for bees.

- In this design, a microclimate convenient for bees is formed. They feel comfortable and breed easier.

- It is easier to control the vital activity and development of the bee colony, to collect the results of its work.

- In such a device, the uterus can be excreted, and there is no need for nuclei.

- A convenient combined bottom device makes it easy to clean the beehive from dead bees and ticks.

Minuses

- Not everyone is happy with this hive and speak of the following disadvantages of its design:

- High hive height. However, this drawback is detected only when using from 10 buildings.

- A large number of structural elements require more costs and time for their manufacture and replacement.

- Lots of empty unallocated space.

Did you know? In the West, Jerjon (Germany), Berlepsh and Langstrot (USA) are considered to be the inventors of hives, who came to the construction of a frame hive independently of Prokopovich in 1851–1852.

DIY beehive manufacturing technology

You can make a Boa’s hive with your own hands, but for this you will need to have the necessary tools and some carpentry skills.

Materials and tools for manufacturing

It is necessary to stock up on such materials:

- a board 14-15 cm wide and 5 cm thick;

- plywood 4 mm thick;

- wooden slats 35 mm thick;

- nails 2.5 cm and 5 cm;

- 5 cm screws;

- foam sheet;

- paint for a beehive (best Pinoteks).

From the tools you will need:

- a circular saw;

- Bulgarian;

- hammer;

- electric drill and drill 12 mm;

- vise;

- furniture stapler with brackets 14 mm;

- measuring ruler and goniometer.

Drawings and Dimensions

Each of the buildings of the Udav hive has external dimensions of 37.5 × 36 × 13.5 cm, which are cut from the boards.

To assemble them, the following parts are made:

- Front and back - dimensions 37.5 × 13.5 cm and a thickness of 3 cm. For their manufacture, first 2 billets 13.5 × 40 cm are sawn out, and then the dimensions are adjusted to the necessary.

- Two side parts are made by parameters 34 × 13.5 cm and a thickness of 2 cm. First, one blank 36 × 13.5 cm is sawn from a 5 cm board and sawed in half. Then they finish these parts to the desired size.

Now it is necessary to cut the folds of the following sizes on the workpieces:

Now it is necessary to cut the folds of the following sizes on the workpieces:- 11 × 15 mm are made to connect the housings and to fix the frames.

- 20 × 20 mm - for connecting the front and sidewalls;

- 15 × 20 mm - on the front and rear walls.

In the front part in the middle, a hole for a notch of 13 mm is drilled. In the sidewall, you can drill a hole for the handle and install it. Then a combined bottom is done:

Then a combined bottom is done:

- Front part. It is made of a bar measuring 37.5 × 9 cm 3 cm thick. On top make a fold 11 × 15 mm, and on the sides - 20 × 20 mm. A 33.5 cm long slit is drilled in the front part, into which a mesh insert is inserted that fits into the grooves of the sidewalls. A feeder can be inserted into the gap between the bottom and liner when the need arises. A removable arrival board 16 mm thick and 31.6 × 6 cm in size is attached to the front.

- Rear end. It has parameters of 37.5 × 5 cm and a thickness of 3 cm. A fold of 11 × 15 mm is made on top, and 20 × 20 mm on the sides. The back is mounted in retractable plywood.

- Two sidewalls. The size of each is 34 × 9 cm and a thickness of 2 cm. At the top, a fold of 11 × 15 mm is made.

The lid for the hive "Boa constrictor" consists of the following parts:

The lid for the hive "Boa constrictor" consists of the following parts:- Front and back. They are made with dimensions of 37.5 × 6.5 cm and a thickness of 2 cm. They make folds with dimensions of 20 × 11 mm on the sides and bottom. A 13 mm tap hole is drilled in front.

- Two sidewalls. The size of each is 34.2 × 6.5 cm 2 cm thick. At the bottom, a fold of 20 × 11 mm is made.

- Top plywood sheet dimensions of 37.5 × 36 cm with a thickness of 4 mm.

- Bottom plywood sheet dimensions of 35.4 × 33.9 cm with a thickness of 4 mm. A hole with a diameter of 3 cm is made in its central part.

- Between sheets of plywood it should be possible to insert a foam sheet measuring 33.5 × 31.8 cm.

The assembly of body parts, the cover and the bottom is carried out using nails and screws. In this case, a right angle is set and protruding parts are removed.

The assembly of body parts, the cover and the bottom is carried out using nails and screws. In this case, a right angle is set and protruding parts are removed.A tin coating measuring 41.5 × 40 cm is attached to the roof and bends 2 cm on the sides. The hive itself is painted with “Pinotex”.

Hive equipment inside

For the internal filling of the hive "Boa constrictor", 9 frames are made of racks 28 × 11 cm in size in each building.

Each apiary has the following sizes:

- Top part - 32 × 2.3 cm with a thickness of 3 mm. In it, a cut is made in the middle for inserting waxes 27 cm long and 2 mm thick.

- Bottom - 28 × 2.3 cm with a thickness of 3 mm.

- Two sidewalls. Each has a size of 10.6 × 3.5 cm and a thickness of 7 mm.

Frame parts are fastened with small carnations or furniture staples at a strictly set right angle. After the hive is assembled and the frames are set, there must be at least 19 mm void inside so that the bees can easily move from one housing to another and brood.

Bee Keeping Rules

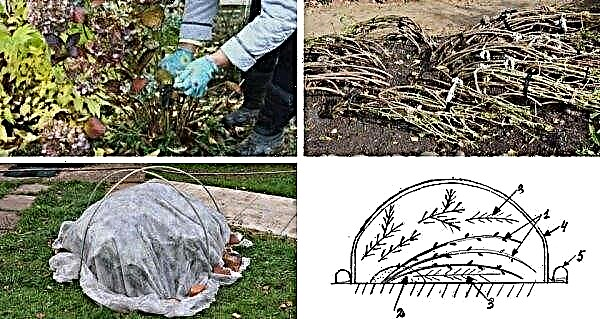

In the hive "Boa" wintering for bees, as a rule, is organized in five buildings. When the wintering is over, and the bees make the first flyby, they need to be taken care of.

Beekeeping in the Boa constrictor hive: video

In the first two buildings from below, insects are usually absent during this period, so they are removed, cleaned of various debris. Then conduct a survey of the inhabitants of the hive. Count the number of bees, the state of the uterus and brood. If everything is in order, the hive is closed.

Depending on the weather and the established air temperature on the street, frames with wax are added and mounted on top of another case. 7-9 days after the first flight, the first building with a wax is installed.

It should be near the brood nest. Subsequent housings, if necessary, are mounted on top. When a situation arises when it is necessary to change the uterus, and also, if it is necessary to prevent the formation of a swarm, they create an artificial swarm. The case with the queen is taken out, and on two sides (bottom and top) placed one more time.

After 3 days, such a new hive is placed near the old bee house so that the working bees gradually move to the new structure. If, during a subsequent examination, it turns out that the insect is cramped, it is necessary to install another building with a wax.

During the onset of the main honey collection, the two lower bodies must be removed, as they are usually empty or filled with bee bread. From other frameworks, honey is pumped out. On average, about 50 kg of honey is obtained from one piece of evidence.

Did you know? Scientists found beehives for bees made by humans on images of Ancient Egypt and some ancient Eastern countries. The earliest of them are from 3 thousand years BC.

For wintering, winged toilers leave a couple of bodies with sealed honey. In the cold period, bees eat about 7-8 kg.

Tips from experienced beekeepers

The experienced beekeepers give the following recommendations regarding the use of the Udav hive:

- With such compact designs that are easy to understand, it is convenient to wander from one place to another.

- Preventive treatments to prevent the appearance of ticks are produced at least 2-3 times a year. Before cooling, this procedure is mandatory.

- For normal air intake, ventilation must be taken into account. For this purpose, holes are made in the axles.

- When collecting parts, make sure that there are no gaps between them. If they still remain to fix this problem, use gaskets or special skirting boards.

- For the manufacture of this design, it is better to choose a tree of such species - cedar, linden, aspen. Such breeds smell pleasantly and keep dry.

- It is necessary to ensure that all elements of wood are smoothly processed. They should not be burrs, sharp fragments.

- To extend the service of such a bee house it is better to color the wood. Further, during operation, coloring is carried out every 2-3 years.

- To prevent the appearance of cracks on dried wood, it is necessary to conduct a drying oil based primer on the outside of the hives, into which light shades are added.

Important! Bee houses should be painted in blue, yellow, blue and white, as these insects do not distinguish other colors. In order for the bees to find their home faster, it is advisable that each evidence differ in color or some part has a different color than neighboring houses.

The Udav hive consists of a number of small-sized cases and has non-standard, but convenient frames and a host of other advantages. It is easy to maintain, but you will have to spend a lot of time making it yourself.